In recent years, digital printing has become a hot topic in the textile printing and dyeing industry. As a new printing production method, digital printing machines have been adopted by more and more printing processing companies after decades of local development. As the main force of production. Why is digital printing so popular in the industry? Today I will analyze it for you.

With the rise of global environmental awareness and the improvement of national environmental protection requirements, the traditional textile printing process with high pollution and high energy consumption is facing a huge crisis, and its market space is gradually shrinking. At the same time, digital printing technology has become increasingly prominent in the market with its environmentally friendly advantages of effectively reducing energy consumption and pollution during the production process. Therefore, contrary to traditional printing and dyeing, which is in trouble, digital printing that complies with the trend of green environmental protection and meets the requirements of sustainable development may usher in a golden period of development and become a "threat" that cannot be ignored by traditional printing.

As an important part of the printing and dyeing industry, printing must also be at the forefront of the industry, based on the basic concept of environmental protection, using innovative technologies to achieve sustainable development of the enterprise. The emergence of digital printing has precisely provided conditions for the green and environmentally friendly production of printing.

Nowadays, the internal industries of the textile industry are constantly adjusting. Coupled with the impact of the epidemic, many printing factories are facing suspension of production. Many people are worried about the prospects of the textile printing industry. Digital printing has attracted much attention. As a new printing method, digital printing has made this industry very popular due to its advantages such as high efficiency, low proofing cost, good printing effect, and less pollution. And there are many advantages.

- Bright colors and clear patterns

The printing accuracy is high, the colors are rich, the transition is natural, and the patterns are clear.

- Personalized customization

There is no need for plate making, the batch size is flexible, there are no restrictions on patterns, and the image can be modified at will. It can achieve both single-piece production and mass production, and the delivery speed is fast.

- Environmentally friendly and pollution-free

Low energy consumption, low pollution, low noise. No waste water is produced during the entire printing process, and the noise is low. It is a truly pollution-free production technology.

The entire production process only relies on one computer, and one person can manage multiple machines at the same time, saving labor costs; it occupies a small space, saving space costs.

As a senior digital printing equipment manufacturer, Fedar Textile Printing has been committed to using its own technical advantages to develop and produce practical printing solutions that meet market demand. With the update and iteration of digital printing technology, it has launched 15-head digital printing machine, FD61915E-A, which increase the printing speed to 610 square meters per hour while ensuring printing quality and equipment operation stability. Once it was launched, it was favored by many users.

FD61915E-A has followed the research and development direction of high-end industrialization from the beginning, and have achieved optimization in terms of equipment printing accuracy, speed, operational stability, and post-management maintenance. In order to reduce customers' purchase costs and machine maintenance costs, so that customers can spend less money, Fedar has achieved the ultimate in cost-effectiveness of the model.

Let’s take a look at the sublimation printer together!

FD61915E-A (click here for more info)

Advantages

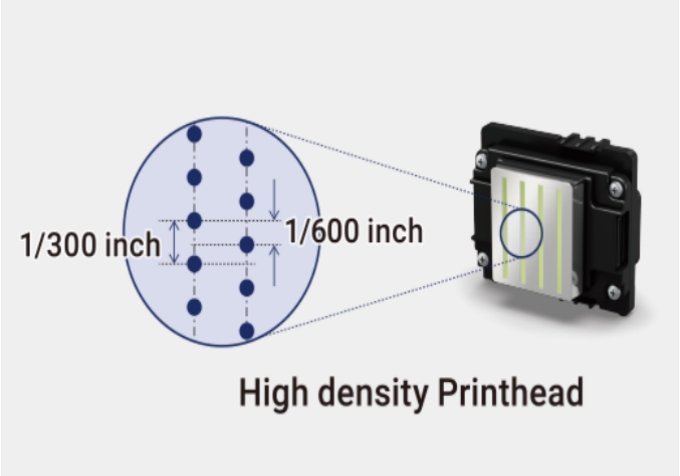

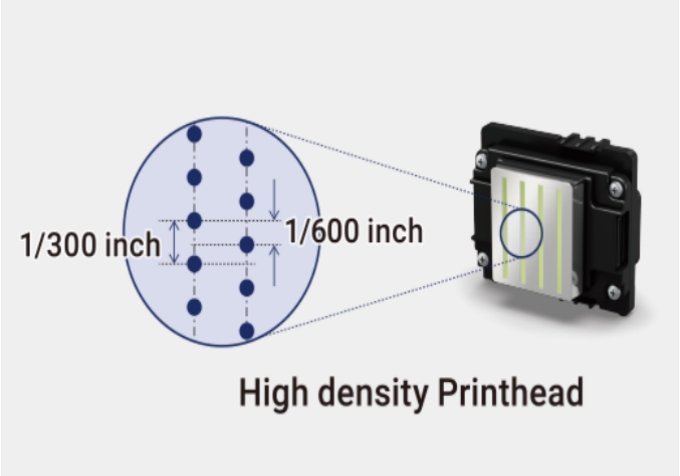

Equipped with 15 Epson I3200-A1 nozzles, the ALL MEMS (Micro Electromechanical Systems) manufacturing process and the use of thin-film piezoelectric components enable high-precision nozzle arrangement (600npi/2 rows), making the print head compact, fast, and of high quality. Good and durable.

It adopts an industrial-grade integrated appearance frame + the overall beam is enlarged and widened: the strength is higher and the machine runs more smoothly.

Fifteen nozzles, the speed can reach 610㎡/h, one nozzle can have more than one nozzle.

The precision nozzles and ink paths made by Epson's unique MEMS technology enable the ejected ink droplets to be close to a perfect circle and accurately positioned at the same time.

Epson's unique VSDT (Variable Ink Droplet Technology) can freely control the size of the ejected ink droplets, thereby reducing the graininess of the picture, presenting more picture details, smoothing the color, and high saturation.

The new nozzle misalignment arrangement solves the problem of inconsistent left, middle, and right effects on the printing platform, improving printing quality by at least 20%.

There is no need for complicated processes such as plate making, printing, and repeated color registration. The operator only needs to use a computer to handle it. The operation is simple and convenient.

- Energy consumption and loss

Fedar digital printing machine supports thin paper printing, allowing manufacturers to save costs and improve work efficiency.

The optional 10,000-meter retractable base enables a flexible layout and maximizes the use of the paper area, reducing resource waste and saving consumable costs.

Fedar digital printing machine is equipped with an adjustable dryer. The manufacturer can adjust the power of the dryer according to actual needs, saving unnecessary electricity consumption.

The use of ultra-high concentration ink saves ink usage, faster drying speed, and lower drying power required, further reducing production energy consumption and effectively reducing production costs.

The whole process of Fedar digital printing machine is controlled by a computer, which reduces the intermediate links such as screen making and pulp mixing, which means reducing the number of workers and saving labor costs.

- Wide range of applications

It can be used in printing factories, clothing factories, personalized customization, online order sales, and other craft factories. The products can be used in clothes, pants, hats, bags, home textiles, and other fields, and have strong adaptability.

- Eco-friendly and pollution-free

On-demand inkjet reduces the waste of chemicals and the discharge of wastewater; the noise during inkjet is low, quiet, and clean, and there is no environmental pollution, achieving a green production process.