Today we come to understand how to install print head of

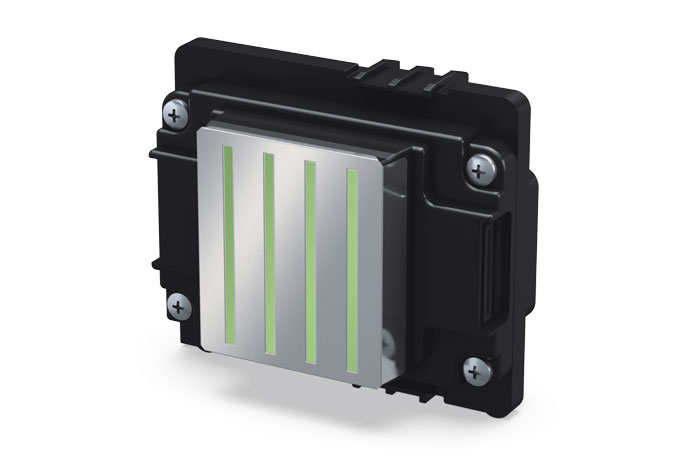

sublimation textile printer. Print head of Fedar sublimation printer is a precision part, and improper operation can easily cause damage or even burn print head of sublimation printer. So how should print head of Fedar sublimation printer be disassembled and installed correctly?

1. Print head of Fedar sublimation printer should be powered off during installation. If it is easy to break print head when it is powered on, gently push trolley to move left and right after installation, and check whether it is smooth and controllable, then print head has been installed. When it is in place, it can be energized.

2. Do not install ink when Fedar sublimation printer is powered on. Check if there is any bad contact, otherwise print head of sublimation textile printer will burn out due to a short circuit.

3. There must be protective measures on surface of print head of Fedar sublimation printer, and do not collide, so as to avoid damage and deformation, which will affect normal operation of sublimation textile printer.

4. At this time, you can add ink. Check ink volume, ink suction pump, and cleaning sheet one by one.

5.Most of sublimation textile printer heads installed for first time have air inside, so print a picture sample to exhaust air before normal printing.

Zhengzhou New Century Digital Technology Co., Ltd.,- (Fedar Printer:

www.fedar.net) has exquisite production technology and professional technical team in the field of fedar sublimation printers,inkjet heat transfer printer,digital fabric printer,etc., focusing on providing comprehensive solution for field of inkjet printing.

Fedar sublimation printer company has absorbed and condensed a group of high-quality professional technicians and enterprising young management groups, formed a strong technical team and increasingly rigorous management system,providing customers with high-quality printing machines and services,and has established a good brand image and reputation in industry.