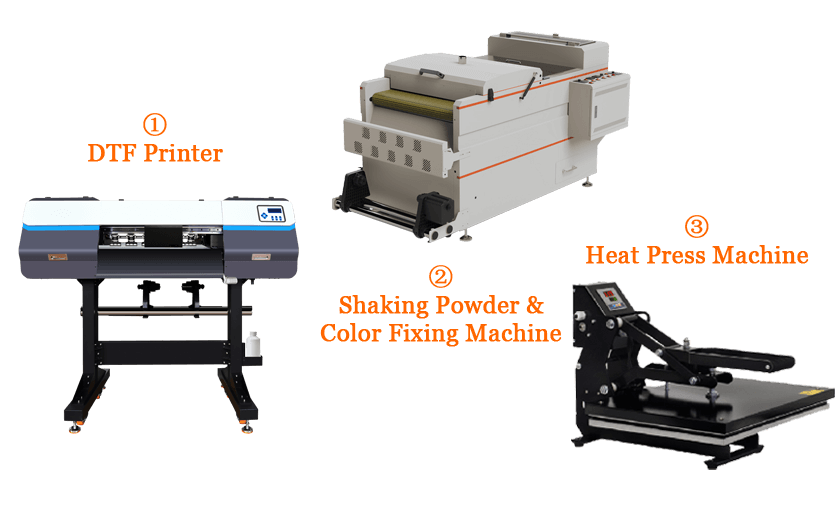

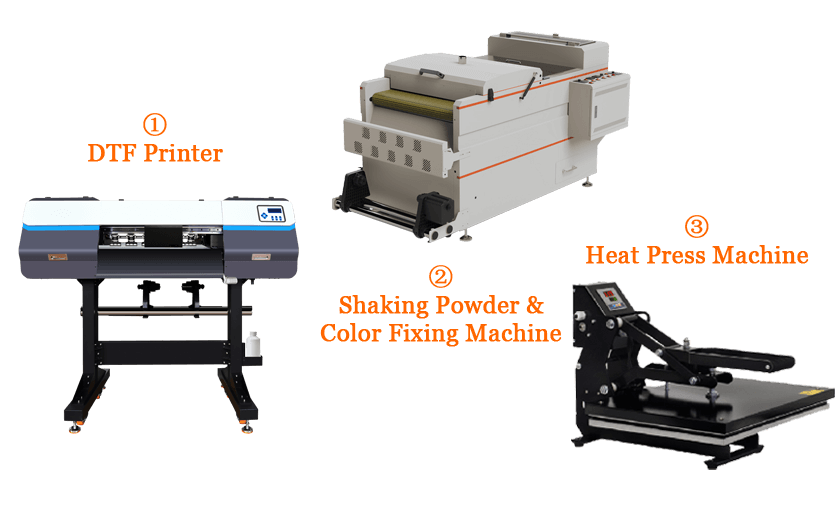

Printing T-shirts is easy, but how to transfer the pattern to the clothes is the most important thing. Next, let's learn about the course of using the DTF Printer to transfer the printed product to the clothes.

DTF transfer process for T-shirts

Step 1 - Printing on DTF Film

First, insert PET film into the printer tray instead of plain paper. Print a white image on the PET film. Then set the color to be printed in the printer and print the image on the white layer.

Step 2 - Shaking the hot melt powder

Sprinkle the hot melt powder evenly on the printed film.

Step 3 -The most common method involves using a heat press machine to melt the powder by pressing the film under its heat

Step 4 - Pre-Pressing

This step is the pre-pressing of printed images before transferring them to printed items (clothing, shoes, hats, masks, etc.) Pressing them under the heat press and heating them for about 2 to 5 seconds.

Step 5 - Print Image Transfer

Transfer the printed PET film onto items like clothes, shoes, or hats under a heat press set to 150-155°C for up to 20 seconds.

Step 6 - Wait for the dtf film to cool

Before peeling off the film, it is important to wait until the finished print has cooled to room temperature before peeling it off, if it has not cooled to that room temperature then it will damage the print and may cause the pattern to fall off or the pattern to be incomplete when the film is torn off.

Common mistakes and solutions in the process of DTF Printing

1. DTF film is crooked or the film is printed unevenlySolution:

a). Make sure the film is properly aligned with the paper feed slot of the DTF printer.

b). Check if there is any dirt on the film and clean it if necessary.

2. The printhead is cloggedThe DTF print head may be clogged with dry ink or white ink (white ink is prone to impurities).

Solution:

a.) We recommend that you unclog the printhead with a professional printhead cleaning solution, often referred to as the Little Blue Bottle.

b). If the printhead clogging persists, we recommend replacing the printhead.

3. Uneven application of adhesive powderSolution: During the printing process, when the ink is still wet, apply the adhesive powder evenly over the entire printed part and shake off the excess powder before curing.

4. Poor quality of the transferred imageSolution: Use professional image design software to maintain the clarity of the image and the high resolution of the image (at least 300 DPI).

Benefits of using DTF to print T-shirts

Cost Effectiveness

When producing customized clothing, it is important to consider the cost. With DTF printing, we can reproduce small batches of designs((100 pieces or more of a design) without spending too much money.

Crisp and firm press-stamp effect

Making use of DTF printing technology ensures that the stamping effect on garments is clear, smooth lines, and the designs are firm, not easy to peel off, and long-lasting.

Versatility

This printing method pertains to diverse materials, including cotton, polyester, nylon, and so much so that leather. You can wear unique customized patterns on a variety of garments, such as T-shirts, sweatshirts, jackets, and more.

Strong ink fixation and rich adhesive particles

The product has strong ink fixation and rich adhesive particles, which ensures a stable and consistent stamping effect, no haloing, presenting a perfect stamping effect.

Strong heat dissipation and no ink dispersion

Even in the process of high-temperature stamping, the product can maintain stability, avoid the phenomenon of scattered ink, and ensure the quality of the stamping.

Excellent washing resistance

After many times washing(Wash more than 40 times and it will still look as good as new), the effect of the stamping is still like new, not easy to fall off or deform.

Environmentally friendly

After transferring DTF PET Film, the paper substrate can be recycled, which is in keeping with the modern green concept and ensures stable product quality, bringing you a safe and reliable new experience of hot stamping.

Conclusion

In short, DTF printers have brought more innovation to garment transfer, if you want to improve your garment business, you need to understand how DTF is transferred to the t-shirts we often wear, as well as in the transfer process need to pay attention to the problems and solutions, I hope the above article can give you some help!

If there's anything we can do to further showcase machines' features, please let us know.

Email: sale@fedar.net

Whatsapp: +86 15515715397

Our company has over 30 models of printers with independent intellectual property rights and patents. Marketed under the esteemed brands of

Skycolor,

Stormjet, and

Fedar brands, these printers cover a wide range, including digital textile printers, UV printers, eco-solvent printers and more. Known for their exceptional quality and performance.