The

FD6198E-3200 heat transfer paper printer is an

8-head digital printing machine developed and upgraded on the basis of market research and repeated consideration and testing by technicians. In actual application, the speed can reach 336㎡/h, which shows the impact on the high-end market.

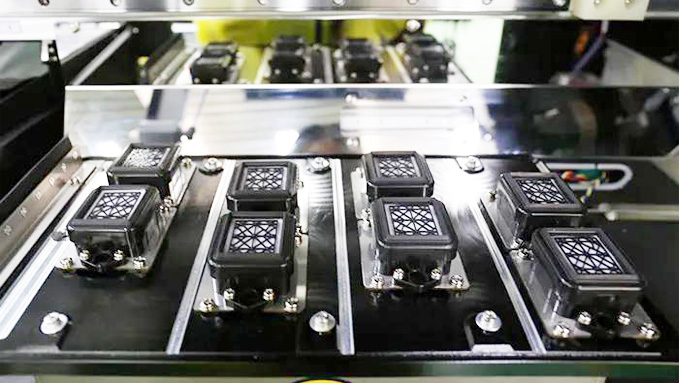

No.1 8 printheads configuration

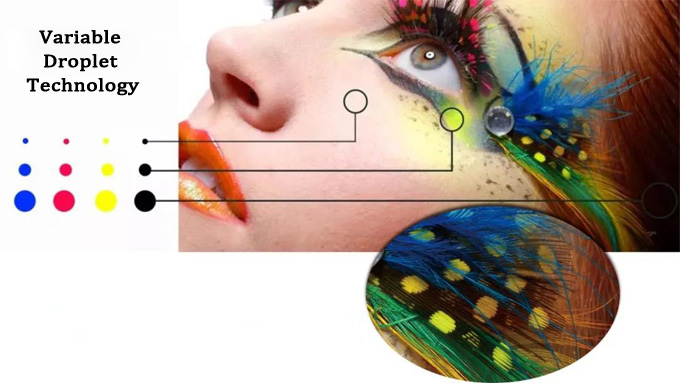

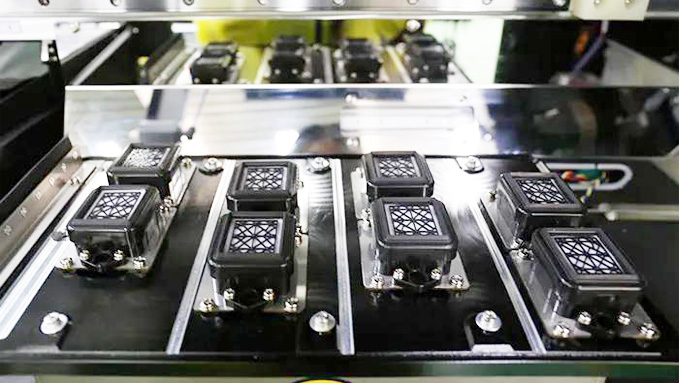

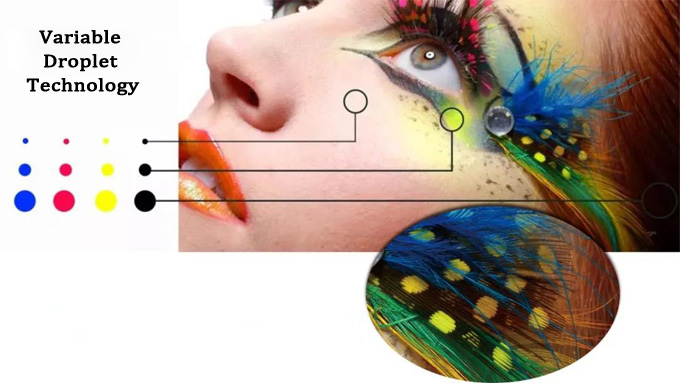

Fedar FD6198E-3200 heat transfer paper printer is equipped with 8 EPS3200 print heads (also known as 4720 print heads). Compared with the double-head and three-head printer in the market, the number of print heads has doubled and the speed has been qualitatively improved. In practical applications, the printing speed is 336㎡/h. The print head adopts TFP film piezoelectric technology + 2.5pl variable dot ink drop function, precise positioning of ink droplets, richer and fuller image color levels, and more exquisite printing effects.

No.2 industrial design

1. The whole frame is welded with square steel, industrial grade design, and the heat transfer paper printer is strong and stable, which ensures that the printer is stable and does not shake during the high-speed printing process

2. The 8 print heads are arranged in a staggered arrangement, which can eliminate feathering and stepping passes, ensuring high-quality output in high-speed printing mode.

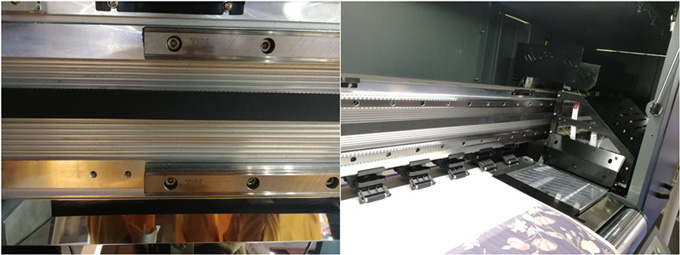

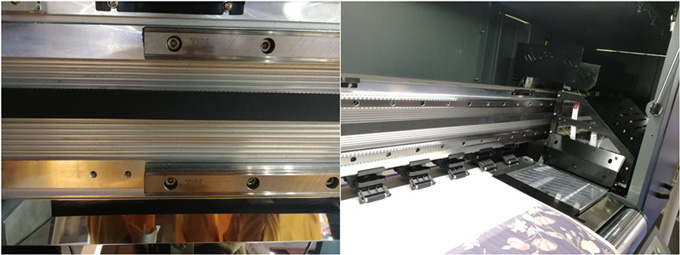

3. The double guide rail design ensures that the carriage runs more accurately and stably.

No.3 Inflatable shaft retracting and unwinding system

During printing machine operation, there is no need to use other accessories to fix the printing medium, and the air pressure is used to automatically adjust. Make the force even, and the paper will be smoother. The rewinding and unwinding system can rewind 1000 meters of paper, and has the characteristics of large load-bearing weight, long service life, uniform loading and unwinding force, and short air deflation operation time.

Compared with other rewinding and unwinding systems, it can rewind and unwind 1000 meters of paper at one time, eliminating the need for frequent paper loading operations, greatly saving manpower and time, and providing continuous high-speed printing. The unique swing bar in the rewinding and unwinding system ensures that the paper is evenly stressed during the entire printing process and the paper is taken up smoothly and tightly.

No.4 high-end quality accessories

Fedar FD6198E-3200 heat transfer paper printer is equipped with high-end quality accessories to further enhance the stability of the printing machine. Such as Japan's THK mute linear guide, Germany's igus ink chain, Leadshine's brushless integrated motor, and the United States imported fluorine rubber press roller, etc., which ensure the printing accuracy and the stability of long-term work.

No.5 humanized functions

Fedar heat transfer paper printer design is more humane, and the overall function is improved from the details, and the equipment is intelligent, automated and industrialized. Such as secondary ink supply system, intelligent drying system, intelligent lack of ink/waste ink alarm system, original two-dimensional feather printing function, new integrated intelligent nozzle cleaning and moisturizing device, etc., make the operation of the heat transfer paper printer easier and more convenient.

As a high-end printing machine in the printing industry, the FD6198E-3200 heat transfer paper printer has unparalleled advantages in reducing costs, increasing production capacity, and environmental protection. It is a magic weapon for enterprises to compete in the era of low profit.