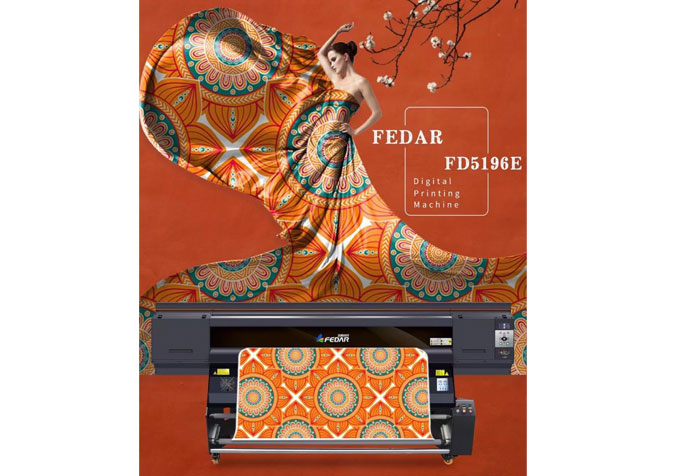

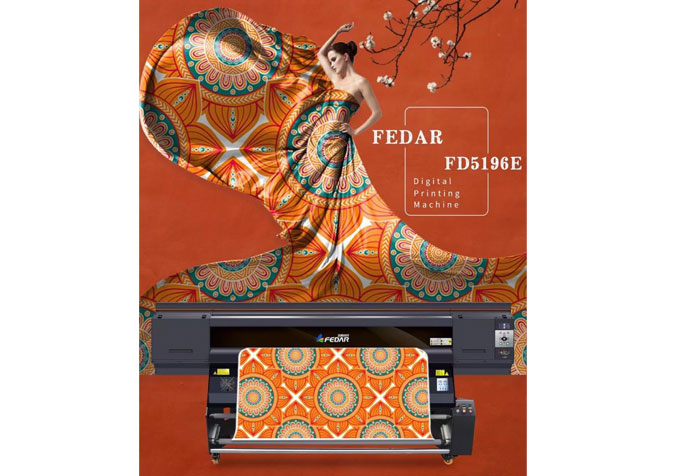

Fedar heat transfer

digital printing machine and Fedar direct-injection digital printing machine have been widely used in the fields of digital printing, textile, advertising, home furnishing and personalized design. The products have passed ISO9001 quality system certification and CE certification, winning the majority of consumers Trust. Through cooperation with world-renowned printhead manufacturers and software suppliers, the latest and most practical technology is integrated into the product, and it has the world's leading clothing plate making system, digital printing system, textile printing and dyeing system, advertising inkjet system, and the overall printing and dyeing industry solution.

1. The quality analysis, improvement method and processing plan of printing image are as follows:

The image definition is not high. Phenomenon: the image is blurred and unclear; there are incomplete graphics in the image: the fineness of the jet printhead is not adjusted properly. The solution is mainly due to the mismatch between the inkjet resolution and the grey fabric: due to the weaving method of the grey fabric, the surface cannot be as smooth as paper. Generally, inkjet printing uses 360-720dpi line inkjet printing. Fine fabrics such as silk fabrics are rarely jetted to 1440dpi, and it will not be effective if the image definition is increased infinitely. And it will affect the increase in injection speed. To increase the difficulty of software and hardware, the resolution should be reasonably selected according to the fineness of the pattern and the finish of the grey fabric. The height of the printhead should be reasonably adjusted for fabrics of different thicknesses: the printhead is too low, it is easy to block the printhead and affect the color of the pattern: the printhead is too high. The ink moves with the left and right of the printhead. There is a certain height from the fabric. Will produce a certain angle of parabola. The borders of the printed pattern will be blurred. The accuracy is poor. The colors are not bright enough. So when printing. Adjust the printhead to the proper height.

2, the color level in the pattern is not rich enough

The phenomenon is: there are two knots in the pattern, and the level transition is unnatural; the color tone is not strong; the level is relatively smooth. The reason is that the dye ink is improperly selected or not suitable for the grey fabric. The solution is: Inkjet printing uses the number of ejected droplets to change the color gradation. Jet printing as a stipple. There is no problem in expressing dark colors with high dot density. Sometimes there is a feeling of poor hierarchy. Or due to the mixing of extra color points, the phenomenon of gray and dark color and reduced color vividness is easy to solve the problem of light-colored areas. The effect of increasing density can be better by using dark and light color materials, and double color materials. Another method is to pre-mix the colors. The so-called "spot color" jet printing. But it must be supported by a color measurement and matching system and an automatic mixing system. And color registration will be restricted.

3, the surface grain size is coarse or ink flow occurs during the printing process

It is caused by improper adjustment or damage of the ink jet port. The solution is: the choice of printing accuracy. Generally, worsted fabrics are mostly printed with high precision 720doi~720dpi. Printing accuracy is directly related to printer resolution. Use 720dpi resolution for fabric printing. The precision is already quite high, and general woolen fabrics can be printed with 360dpi~360dpi precision. This can increase the printing speed. And enough to meet the printing accuracy.

4, the dye ink bleeds after printing

Due to the small volume of the fabric printing part that can absorb ink. Under the action of the capillary effect. Excess ink on the surface of the fabric diffuses along the capillaries between the fibers, causing the inkjet printing pattern to bleed. The main factor that affects the penetration of paint ink on the fabric is the composition of the ink itself. Fiber type and fabric structure and specifications are also very important factors. The solution is: treat the fabric with a suitable thickener. Block the gaps between the fibers. Prevent ink from spreading along the capillary. For light and loose fabrics, the gap between the fibers is large and the water holding capacity is poor.

Zhengzhou New Century Digital Technology Co., Ltd.,- (Fedar Printer:

www.fedar.net) has exquisite production technology and professional technical team in the field of fedar sublimation printers,inkjet heat transfer printer,digital fabric printer,etc., focusing on providing comprehensive solution for field of inkjet printing.

Fedar sublimation printer company has absorbed and condensed a group of high-quality professional technicians and enterprising young management groups, formed a strong technical team and increasingly rigorous management system,providing customers with high-quality printing machines and services,and has established a good brand image and reputation in industry.