In process of using

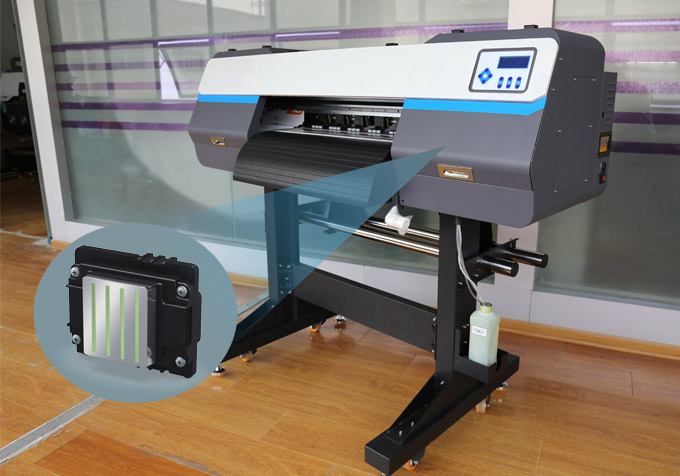

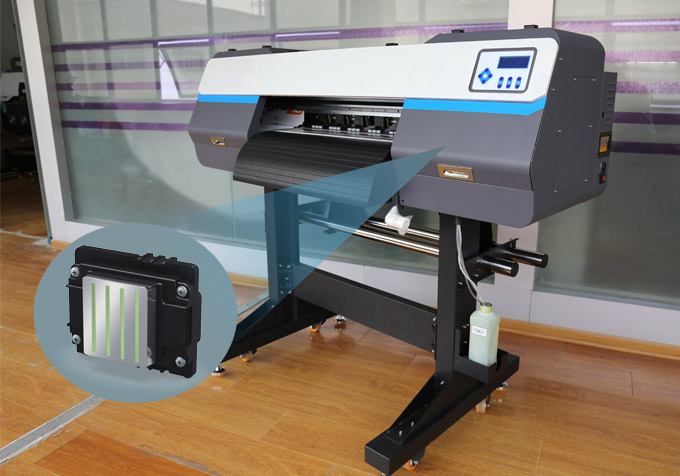

70cm DTF printer, pay special attention to maintenance of printhead. When printhead is clogged, how should it be cleaned? Fedar DTF printer manufacturer summarized some precautions for cleaning printhead.

1. Process of manually cleaning DTF printhead should be carried out according to steps in operation requirements.

2. When cleaning printhead, a thin rubber tube can be put on front end of medical syringe, and cleaning fluid can be used for flushing. When flushing, use a magnifying glass to carefully observe nozzle. If there is siltation residue beside nozzle, use a soft rubber product to remove it. Integrated print head that has been left unused for a long time is easy to block printheads due to ink drying, and can be cleaned after soaking in hot water.

3. Do not use sharp objects to clean printhead of 70cm DTF printer, do not hit printhead, and do not touch printhead with your hands.

4. Do not disassemble or install sprinkler when it is energized, and do not touch electrical contacts on sprinkler with your hands or other objects.

5. Printhead of cannot be removed from Fedar DTF printer and placed alone, and printhead cannot be placed in a dusty place.

Zhengzhou New Century Digital Technology Co., Ltd.,- (Fedar Printer:

www.fedar.net) has exquisite production technology and professional technical team in the field of fedar sublimation printers,dtf printer for t shirts, inkjet heat transfer printer,digital fabric printer,etc., focusing on providing comprehensive solution for field of inkjet printing.

Fedar sublimation printer company has absorbed and condensed a group of high-quality professional technicians and enterprising young management groups, formed a strong technical team and increasingly rigorous management system,providing customers with high-quality printing machines and services,and has established a good brand image and reputation in industry.