In the field of digital intelligent printing, dye sublimation has long been a popular printing, known for its bright colors, durability and versatility. But what exactly is dye sublimation? How does it work? This article will take a deep look at the advantages of dye sublimation printing.

Sublimation printing, also known as sublimation heat transfer, uses heat to transfer dyes to materials such as fabrics, ceramics, metals, and plastics. The sublimation transfer dye is printed on paper (or plastic film), and then the printed paper (or film) is placed over the fabric and heated and pressurized. The dye on the paper (or film) is sublimated into a gas phase and transferred to the fabric. This produces a high quality, long lasting print effect.

The dye sublimation printing process involves several key steps, each of which is critical to achieving high-quality prints. Here's a detailed look at how a dye sublimation printer works:

1. Design CreationThe first step in dye sublimation printing is to create a design using graphic design software such as Maintop6.1、Photoprint. ONYX、NeoStampa.

2. Printing the designOnce the design is finished, it is printed on special sublimation transfer paper using a sublimation printer.

3. Preparing the SubstrateThe substrate is the material onto which the design will be transferred. Common substrates include polyester fabrics, coated ceramics, metals, and certain plastics.

4. Heat TransferThe printed transfer paper is placed on the substrate and both are loaded into a heat press. The heat press applies heat and pressure to the transfer paper and substrate. The temperature typically ranges from 350°F to 400°F (175°C to 205°C), and the duration can vary from 30 to 60 seconds, depending on the material.

5. Cooling and FinishingAfter the transfer is complete, the substrate is allowed to cool. Once cooled, the transfer paper is removed, revealing the final printed design.

4 Greatest Benefits of Sublimation Printing

Sublimation printing offers a variety of advantages that make it a popular choice for a wide range of applications:

1. Vibrant and durable printsSublimation printing produces vibrant, full-color prints that are embedded into the substrate, resulting in prints that resist fading, peeling and cracking.

2. Wide range of applicationsSublimation printing is versatile and can be used on a variety of materials, making it an ideal choice for custom apparel, promotional products, home décor, and more.

3. Environmentally friendly processThe dye sublimation printing process produces minimal waste compared to traditional printing methods. The inks used are water-based and non-toxic, making it an environmentally friendly choice.

4. Affordable for both short and long runsSublimation printing is suitable for both short and long runs without the need for expensive equipment and printing plates.

Key Applications of Dye Sublimation Printing

1. Custom ApparelOne of the most prominent applications of dye sublimation printing is the creation of custom apparel. This includes:

T-shirts and hoodies: Dye sublimation allows for full-color, all-over printing on T-shirts and hoodies, making it ideal for custom designs, sports team uniforms, and promotional items.

Sportswear: The durability and vibrant colors of dye-sublimation prints make them perfect for sports jerseys, leggings, and other athletic apparel.

Fashion items: Designers use dye sublimation to create unique, high-quality fashion items with intricate patterns and colors.

2. Home DecorDye sublimation printing is widely used in the home decor industry to create personalized and stylish items such as

Pillows and Cushions: Custom printed pillows and cushions add a personal touch to any living space.

Curtains and Drapes: Sublimation printing allows you to create custom curtains and drapes with vibrant colors and patterns.

Wall Art: High-quality prints on canvas and metal are popular choices for wall art, adding a touch of elegance to homes and offices.

3. Promotional ProductsCompanies often use dye sublimation printing to create promotional products that stand out. Some common promotional products include

Mugs: Custom printed mugs with company logos or personalized designs are popular promotional products.

Mouse Pads: Dye sublimation printing ensures that designs on mouse pads are vibrant and long-lasting.

Cell Phone Cases: Custom phone cases with unique designs are a great way to promote a brand or create personalized gifts.

4. Photography and Fine ArtPhotographers and artists use dye sublimation printing to create high-quality prints of their work. This includes

Photo prints: Dye sublimation prints on metal or canvas offer a high-resolution, durable alternative to traditional photo prints.

Art Prints: Artists can reproduce their work with incredible detail and vibrant colors using dye sublimation.

5. Signage and DisplaysDye sublimation printing is also used in the creation of signage and displays for various purposes, such as

Banners and Flags: Custom printed banners and flags are widely used for events, trade shows, and advertising.

Trade Show Displays: Dye sublimation printing allows for the creation of eye-catching trade show displays that attract attention.

6. Textiles and FabricsIn addition to apparel, dye sublimation printing is used for a variety of textile applications, including

Custom Fabrics: Designers can create custom fabrics with unique patterns and colors for use in fashion, upholstery, and more.

Soft Signage: Dye sublimation on fabric is used for soft signage, such as backdrops and banners, providing a lightweight and portable solution.

The model recommended this week is designed primarily for

small and mid-sized manufacturers with average order volumes and high on-time requirements. It is synonymous with "

economy". Fedar's classic

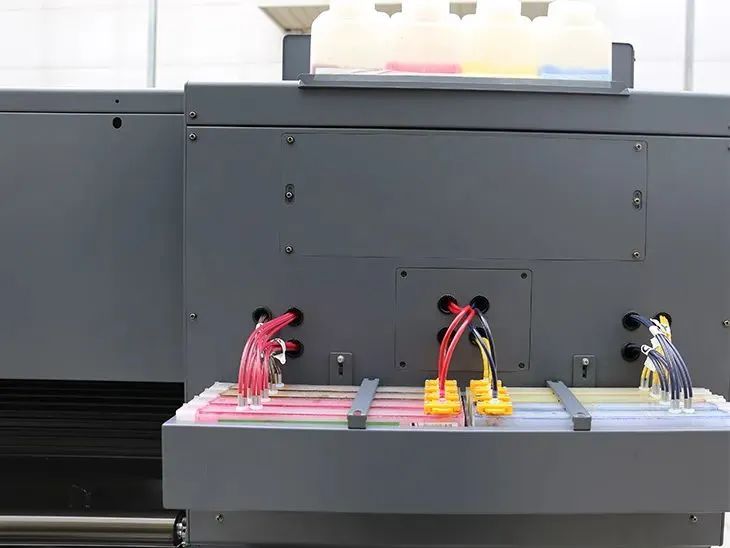

8-head digital printer - FD5198E-A, equipped with

8 Epson I3200-A1 print heads, can print 370m²/h at high speed. It has strong performance and is very popular in the market!

New reinforced beam + high precision support: the machine runs more stable and the print quality is more exquisite.

Double ultra-quiet THK S-class linear guideways imported from Japan: can effectively reduce the resistance and noise of the ink carriage during high-speed movement, ensuring smooth operation of the guideways with less noise.

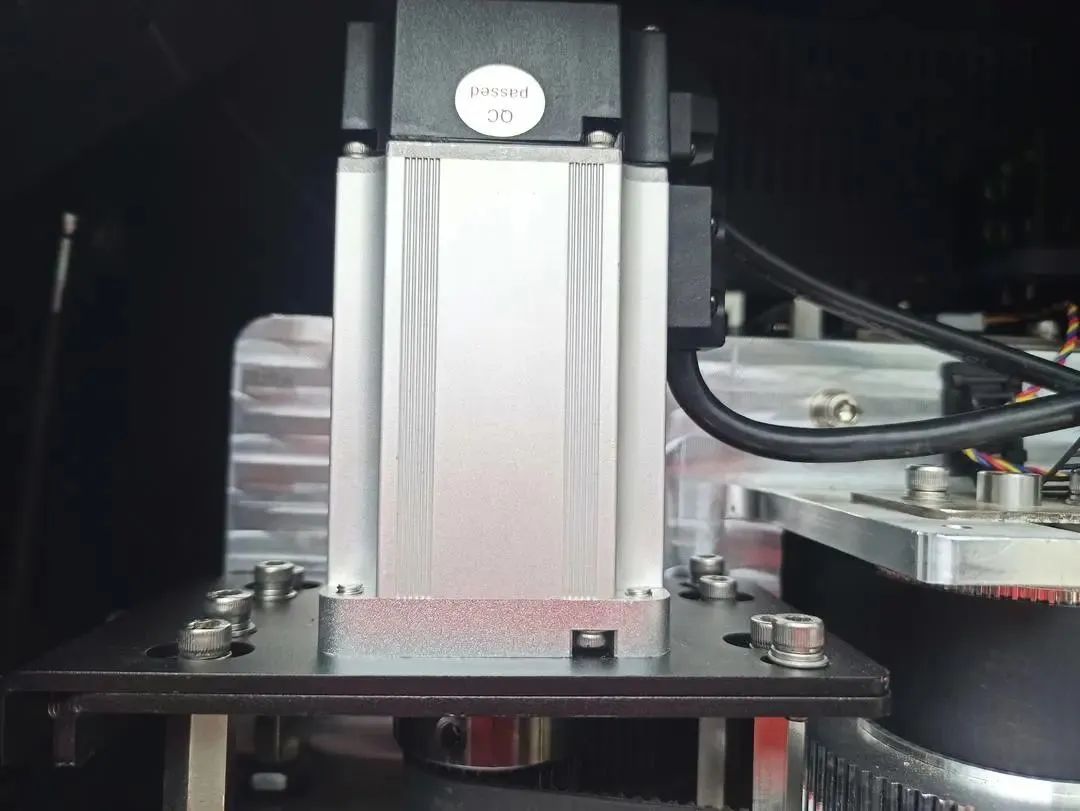

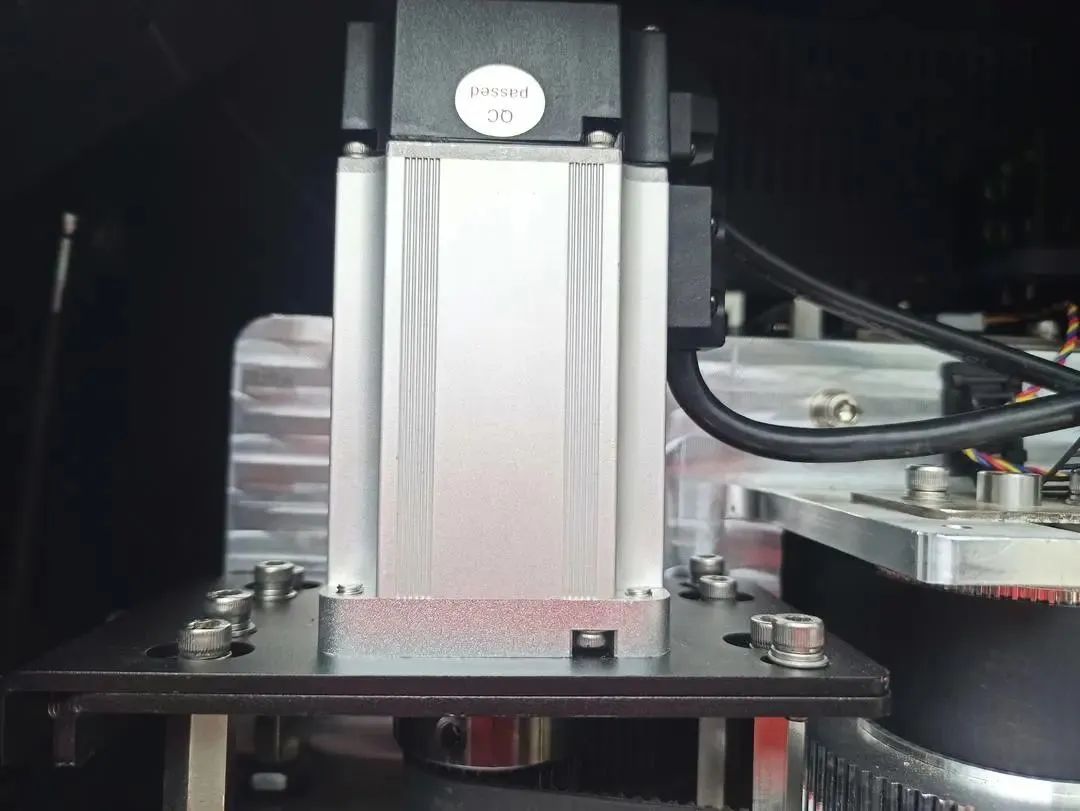

Ultra-high power independently driven servo motor: high-precision drive linear decoding, higher accuracy, smaller linear error and more stable performance.

High-standard platform, beam calibration method, unique S-shaped suction printing platform: easy to adjust, strong paper adsorption.

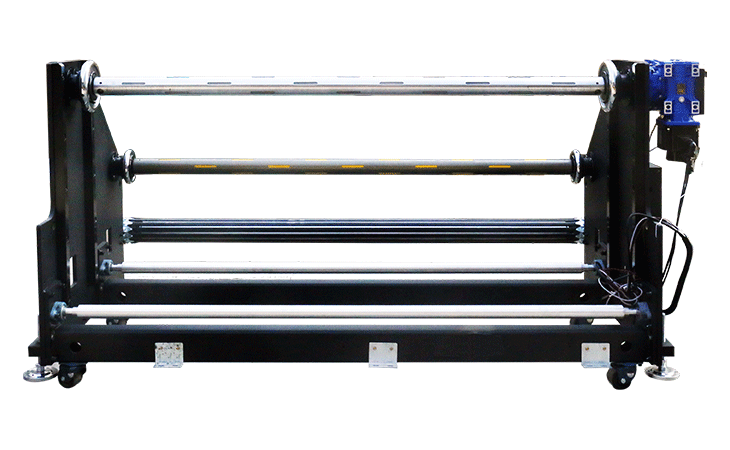

The double damping rubber roller paper expansion device makes operation more comfortable.

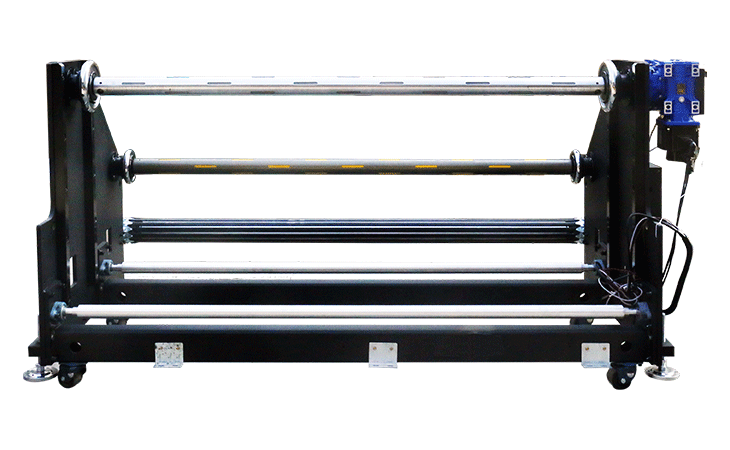

The retractable and deployable system is modular and can be equipped with a 10,000-meter base, depending on customer requirements.

High quality imported accessories: Igus drag chains imported from Germany, NSK bearings imported from Japan.

The swing-rod type constant tension retracting and releasing control system is adopted: it ensures that the paper is tensioned evenly throughout the printing process, and the paper is collected flat and tight to prevent loose retraction.

Standard 2000m (roll diameter 480mm) retractable system, optional 10,000m base: easily achieve direct printing on source paper with a diameter of less than 90cm.

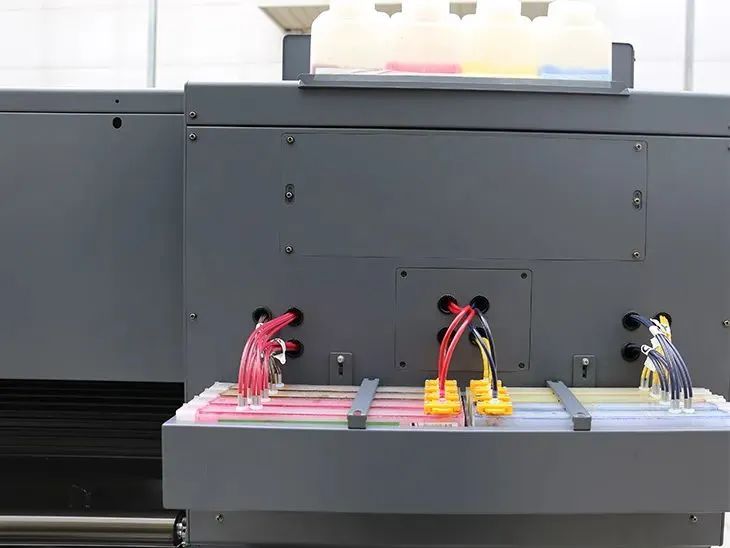

Optional 15L high-capacity continuous ink supply system: Long-lasting printing without ink interruption, ensuring image output quality.

Industrial-grade turbine screw feed and unwind motor ensures stable operation of paper feed and unwind.

If there's anything we can do to further showcase machines' features, please let us know.

Email: sale@fedar.net

Whatsapp: +86 15515715397

Our company has over 30 models of printers with independent intellectual property rights and patents. Marketed under the esteemed brands of

Skycolor,

Stormjet, and

Fedar brands, these printers cover a wide range, including digital textile printers, UV printers, eco-solvent printers and more. Known for their exceptional quality and performance.