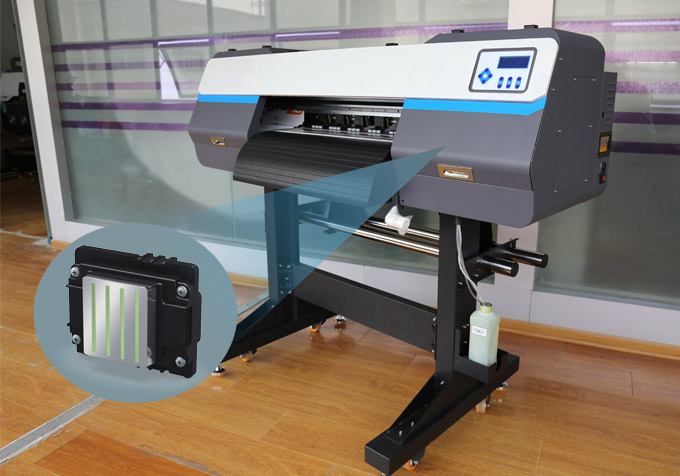

What is DTF shirt printer?

DTF printer, also called direct to film printer, is currently most popular T-shirt printing solution. DTF shirt printer uses pigment ink to print directly on pet film. After being cured at a high temperature by powder shaker, it is transferred to fabrics. Printed fabrics feel soft and have high color fastness, excellent breathability.