03

Jan

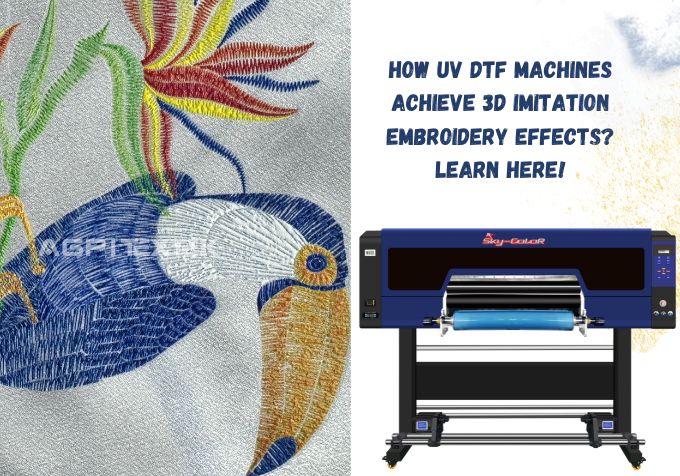

How do UV DTF machines achieve 3D imitation embroidery effects? Learn how they work, their advantages, and their various applications.

Embroidery has always been admired for its textured look that makes a fabric design stand out. However, traditional embroidery is time-consuming and expensive. The UV DTF (direct-to-film) machines present a whole new way of achieving an embroidery effect almost like traditional embroidery with greater efficiency and the results are just amazing.

Can these machines accomplish 3D imitation embroidery as well as the traditional method? In this article, we will look at the capabilities, uses, and benefits of a UV DTF machine and why it's truly an innovation, especially for embroidery.

A UV DTF machine is a combination of UV printing technology with direct-to-film transfer processes, which helps provide durable printouts that can be transferred onto different materials, such as textiles, ceramics, metals, etc. Now you don't have to wait for your digital print to dry, UV DTF machines instantly cure the print with UV light and you get vibrant and detailed designs.

UV Curing Technology: This feature makes the printed design dry immediately to avoid smudging and makes it longer-lasting.

Material Compatibility: UV DTF machines can print on fabrics, plastics, glass, leather, and many other surfaces due to their versatility.

High-Resolution Prints: These machines are capable of printing complex designs, which are ideal for making three-dimensional effects.

Eco-Friendly Inks: Most UV DTF machines employ environment-friendly inks, which is attractive to companies that want to be eco-friendly.

The ability of UV DTF machines to copy embroidery is due to their printing and layering techniques:

1. Layering

UV DTF machines use ink layer by layer, and this builds up the texture. By controlling the thickness of these layers, printers can produce an embroidery-like effect.

2. Textured Printing

Special software and printer settings allow for textured prints. These textures are very close to embroidery threads like satin-, chain-, or cross stitches.

3. Gloss and Matte Finishes

UV DTF printers allow you to choose between gloss or matte finishes, another dimension to the design. The light play on these finishes makes the 3D effect lively.

4. Multi-Layer Ink Application

Using white ink as a base layer makes other colors pop and adds to the raised effect, making designs look like real embroidery.

By combining these, UV DTF machines can produce designs that look embroidered and feel textured, a very close replica of traditional embroidery.

Here are some of its most common applications:

1. Fashion

UV DTF machines are getting popular to print embroidered designs on garments. Cutting out actual perforation of the materials greatly reduces the cost and time typically associated with standard embroidery.

2. Accessories and Footwear

With the help of UV DTF machines, designers embellish bags, hats, and footwear. The 3D imitation embroidery effect enhances the visual appeal and uniqueness of these items.

3. Home Decor

Highly personalized designs with rich textures and vivid colors are now rendered on home decor items like cushion covers and wall hangings with UV DTF technology.

4. Promotional Products

Businesses use UV DTF machines to create promotional items like tote bags, caps, and banners. The embroidery-like designs make these products stand out.

5. Corporate Branding

UV DTF machines are used by companies to embroider uniforms and accessories that bear the corporate logo with an elegant finish. The application of three dimensions enhances the general appearance of logos and designs.

Why are UV DTF machines so popular? Here are the benefits:

1. Cheaper

Embroidery is expensive in labor and materials. UV DTF machines simplify the process, save you money, yet produce great results.

2. Faster

UV DTF is faster than embroidery, perfect for bulk production or tight deadlines.

3. Design Flexibility

No design is too complex for UV DTF. From intricate patterns to multi-color images, it can do it all.

4. Long Lasting

UV inks are durable and will not fade over time. So UV DTF prints are perfect for items that get used or washed frequently.

5. Eco-Friendly Solution

Many UV DTF machines use inks with low VOCs, which matches environmental sustainability. The reduction of material waste compared to embroidery also makes it eco-friendly.

6. Scalable

From one piece to thousands, UV DTF machines can scale to your production needs, perfect for small businesses or big enterprises.

UV DTF machines have many benefits but here are some of the challenges:

1. Cost

Buying a UV DTF machine can be expensive and may not be feasible for small businesses.

2. Learning Curve

Operating a UV DTF machine and mastering the software takes training and experience to get good results.

3. Maintenance

Regular maintenance is required to keep the machine running and to avoid costly repairs.

But the long term benefits of UV DTF machines far outweigh the initial challenges for most businesses.

UV DTF machines have changed the way we apply designs to materials, a realistic alternative to embroidery. By using advanced printing technology, they produce 3D imitation embroidery effects that add value and beauty to products across industries.

Whether you are in fashion, home decor, or promotional branding, UV DTF is a cost-effective, efficient, and sustainable solution. While the initial investment and learning curve may be a challenge, the benefits – from design flexibility to durability – make UV DTF a game changer in printing.

Get creative with UV DTF now!