If

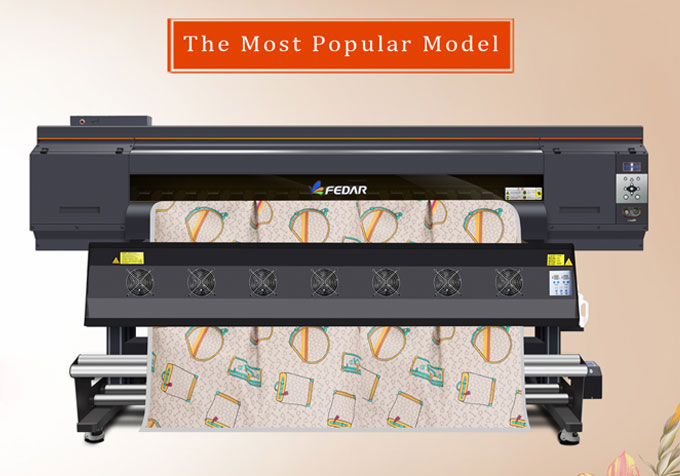

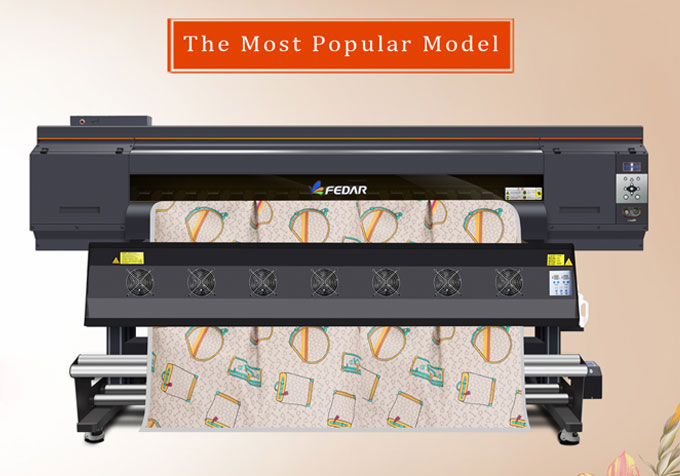

sublimation t shirt printer is not used for more than two days, ink in print head of Fedar sublimation printer must be cleaned, otherwise ink in print head will dry up due to gradual volatilization of solvent, and even damage print head in severe cases. So how do we usually maintain nozzles?

1. After use, move Fedar sublimation printer head to capping station. Do not turn off power before print head reaches capping station. This will cause ink in nozzle to dry and cause damage to print head.

2. Unplug ink supply tube on print head of Fedar sublimation printer, and then use a syringe to draw out nozzle cleaning agent to clean print head of sublimation t shirt printer. It should be noted that do not blow clean residual nozzle cleaning agent in t shirt printer nozzle. Be sure to leave enough cleaning agent inside sublimation printer nozzle so that cleaning agent can moisturize nozzle.

3. Put treated Fedar sublimation printer head into a clean corrosion-resistant container and seal it up and store it for about 1 month.

4. Normally, if print head of Fedar sublimation printer is blocked, it should be soaked in nozzle cleaning agent. When agglomeration is softened, use a syringe to absorb nozzle cleaning agent for flushing. This method generally can solve problem of clogging.

Zhengzhou New Century Digital Technology Co., Ltd.,- (Fedar Printer:

www.fedar.net) has exquisite production technology and professional technical team in the field of fedar sublimation printers,inkjet heat transfer printer,digital fabric printer,etc., focusing on providing comprehensive solution for field of inkjet printing.

Fedar sublimation printer company has absorbed and condensed a group of high-quality professional technicians and enterprising young management groups, formed a strong technical team and increasingly rigorous management system,providing customers with high-quality printing machines and services,and has established a good brand image and reputation in industry.