In the process of using the fedar thermal printer, waste ink will be generated. Why is this? Let’s take a brief look with the fedar printer company.

The situation that a large amount of waste ink is generated in the printing process of the fedar thermal printer is mainly concentrated on the inkjet printer with a split design. The main reason is that the split structure is used: because only the ink cartridge needs to be replaced, the joint between the printhead and the ink cartridge It is easy to enter the air, and the ink can not flow smoothly, causing the disconnection phenomenon in the printing.

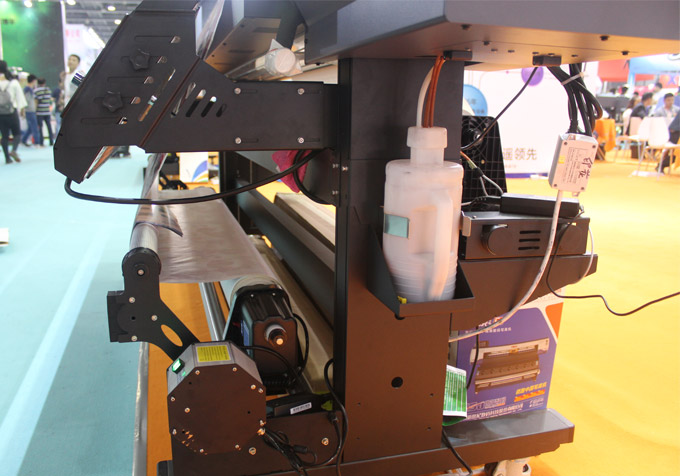

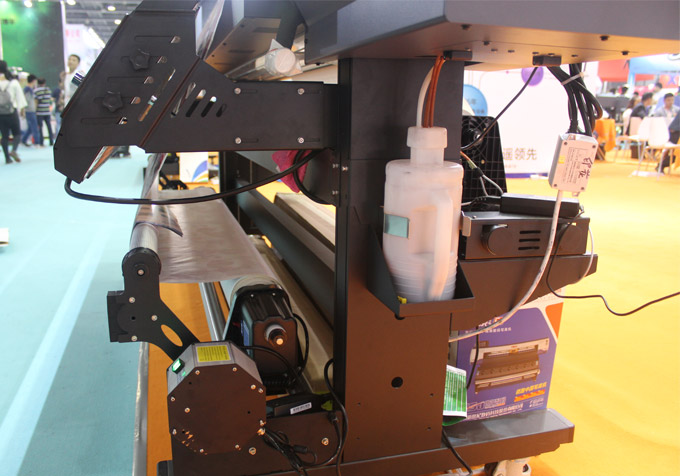

In order to solve the problem of printing disconnection, all inkjet printers are equipped with a hardware system for ink cleaning and nozzle maintenance on the far right side of the machine. The rubber scraper made of rubber is installed inside the printer, and the dirt attached to the nozzle surface is scraped off with the rubber scraper; at the same time, the ink cart automatically returns to the "nozzle protection seat" after the printer stops printing, and the sealing function of the "nozzle protection seat" is implemented seal for a short time to prevent the ink of the print head from clogging up.

For split models that are prone to disconnection, the manufacturer uses a more comprehensive nozzle cleaning and dredging system. That is, under the "nozzle protection seat" there is a special pump attachment for cleaning the nozzle, which regularly draws ink from the ink cartridge. Let each color ink pass through the nozzle, and finally eject from the nozzle to clear the pipeline to ensure the purpose of unblocking. These multiple colors of ink ejected from the nozzle are finally mixed together to become waste ink.The manufacturer has set up a separate plate at the bottom of the printer, called the waste ink tank, and the generated waste ink directly enters it.

The inkjet printer of the one-piece design replaces the nozzle when the ink cartridge is replaced, so there is no pump attachment, and there is no ink cleaning. It generates very little waste ink. The waste ink tank is under the "nozzle protection seat". The remaining ink scraped off by the scraper will be condensed in the waste ink tank over time.