30

Aug

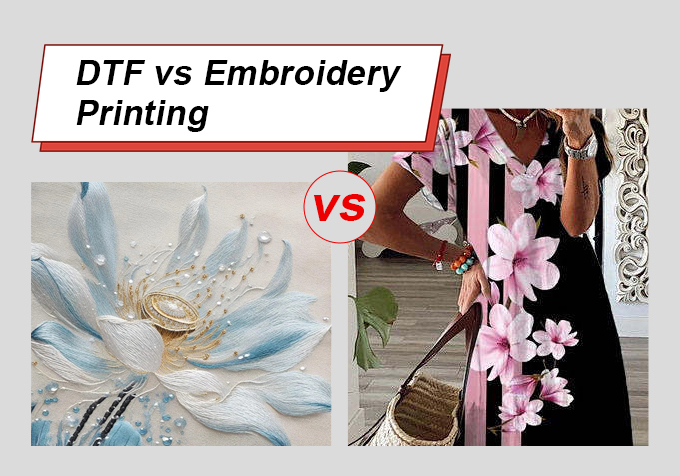

When selecting a printing process for apparel, embroidery and direct-to-film (DTF) printing are two popular options to consider. Yet, what is the difference between the two?

In recent years, customized apparel has experienced an increase in popularity. As demand rises, your decision on a printing method will affect the quality, cost, and satisfaction of your customers. Picking the correct approach might give you an edge over your competitors.

With the customized apparel market expected to grow by over 7.22% annually, now is the time to explore your options. This article will teach you the key distinctions between DTF and embroidery.

Direct-to-garment (DTF) printing uses heat to transfer graphics from a specific film to clothing. Works well with a wide variety of fabrics, such as cotton and polyester.

Instead of printing the pattern onto cloth, embroiderers sew the designs directly into the fabric. Ideal for heavier materials (like denim.)

Visuals: DTF's images are non-textured but vibrant and detailed. Embroidery offers a textured, velvety look.

Durability: Embroidery is, in most cases, more durable than DTF. But, DTFs, when applied to high-quality fabrics using the right methods, may resist fading and peeling for quite some time.

Texture: DTF is smooth; embroidery is raised.

Equipment: DTF requires a printer and heat press; embroidery needs an embroidery machine.

Here are some important factors to keep in mind while deciding between DTF printing and embroidery:

DTF Printing: Ideal for intricate, multi-colored designs, especially those involving gradients and fine lines. If your design necessitates vibrant colors or intricate details, select DTF.

Embroidery: Higher up-front expenses, but perhaps more economical in the long run. This is especially true for bulk order and those requiring a long-lasting, premium finish.

DTF Printing: Perfect for on-demand printing or smaller to medium-sized orders. An ideal option if you prioritize production versatility.

Embroidery: Much better for large orders. For mass manufacturing, it's the way to go since the per-unit cost drops with bigger orders.

DTF Printing: More cost-effective for small orders or one-off designs due to lower setup costs.

Embroidery: Although more expensive up front, it may end up saving you money in the long run, particularly if you're ordering in bulk and want a high-quality finish that will last.

DTF Printing: Works well with many different types of fabric, such as cotton, polyester, and blends. Excellent for a wide range of garments.

Embroidery: Perfect for uniforms, polos, and heavier, more long-lasting textiles. Fabrics that are too thin or too elastic may not be able to withstand the stitching.

DTF Printing: Provides acceptable longevity, although regular washing can cause it to fade or crack. Choose DTF for goods that are less prone to wear and tear.

Embroidery: Very durable, it can withstand intensive use and regular laundering without sustaining significant wear. Best suited for items that require long-term durability,

DTF Printing: Offers a vibrant, silky finish that is well-suited for casual wear or fashion-forward designs.

Embroidery: This method provides a high-end, textured appearance that is ideal for luxury items, uniforms, and professional branding.

DTF Printing: Designed to be more easily personalized and adjusted to suit personal tastes. Ideal for personalized items (names, custom artworks, numbers, etc.)

Embroidery: Personalization is feasible, but it's not as easy or quick as you would with DTF. It works well with logos and other repetitive designs.

DTF Printing: Greater efficiency for one-offs or smaller quantities. Ideal for quick orders and time-sensitive projects.

Embroidery: Slower manufacturing, especially for intricate or expansive designs. Choose embroidery if you have more time and need a premium finish.

DTF Printing: To make DTF more sustainable, you may use recyclable films and environmentally friendly inks.

Embroidery: Thread waste and energy consumption can be higher, but sourcing sustainable threads can reduce the environmental footprint.

DTF Printing: It works well for promotional goods that need intricate patterns, as well as for fashion and casual wear.

Embroidery: Perfect for business attire, uniforms, or anything else that requires a polished and long-lasting finish.

Demand for customized clothing is on the rise in the fashion business. Especially due to consumer desire for personalized, one-of-a-kind items.

DTF Printing: Increasingly popular due to its ability to produce vibrant, detailed designs quickly and affordably. It appeals to businesses that need flexibility and fast turnaround times.

Embroidery: Remains a favorite for high-quality, durable finishes, especially in luxury markets and corporate apparel. Many still prefer embroidery's classic, professional look.

Recent market data suggests a rise in the popularity of DTF printing, particularly among small businesses and e-commerce platforms. The ease of use and lower initial costs are major factors.

Nevertheless, embroidery remains popular in industries that prioritize long-term use and a high-quality appearance, including branded apparel and uniforms.

Texture and Appearance: Customers often choose DTF for its smooth and soft feel.

Durability: While DTF offers good durability, especially with proper care, embroidery still outperforms in terms of longevity.

Feedback: When shopping for casual or stylish products, many consumers rave about DTF, praising it for its vivid colors and capability of producing intricate designs.

Depending on your needs, DTF printing and needlework have different benefits. For complex, vivid patterns and for smaller quantities DTF is affordable and perfect. Embroidery, on the other hand, excels in durability and in providing high-end textured finish.

When deciding between DTF and embroidery, examine your company's objectives, consumer preferences, and budget.

If you're not sure which method is right for you, Fedar offers professional advice and high-quality DTF printing equipment to assist you. Fedar, with its solid reputation for high-quality goods and great customer service, can help you optimize your printing operations.

If there's anything we can do to further showcase machines' features, please let us know.

Email: sale@fedar.net

Whatsapp: +86 15515715397

Our company has over 30 models of printers with independent intellectual property rights and patents. Marketed under the esteemed brands of Skycolor, Stormjet, and Fedar brands, these printers cover a wide range, including digital textile printers, UV printers, eco-solvent printers and more. Known for their exceptional quality and performance.