Daily maintenance is indispensable if you want

DTF t shirt printer to be in best operating condition at all times. So in daily maintenance process, what are parts that need to be checked? Fedar DTF printer manufacturer will answer for you.

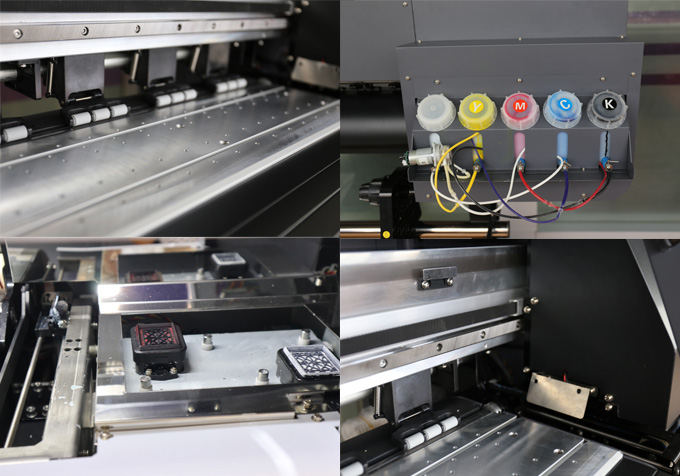

1. Cleaning bottom of printhead of DTF printer: Move trolley to left position, and wipe edge of printhead protection block with a cotton swab dipped in cleaning fluid, once a week, to achieve a clean effect.

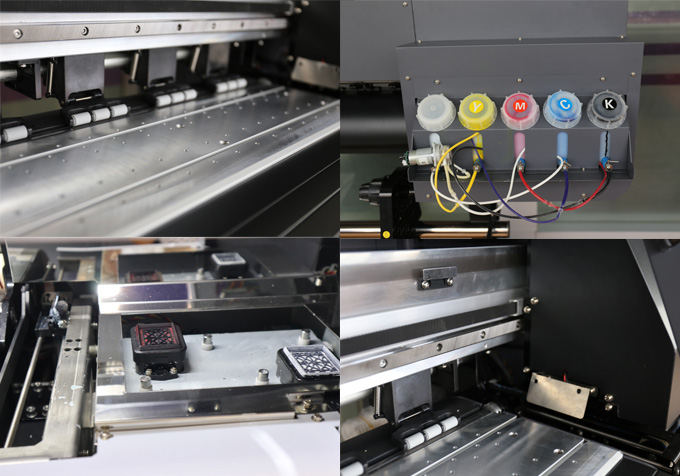

2. Wipe blade cleaning: wipe edge of blade with a cotton swab dipped in cleaning fluid, once every 10 days, to keep it clean.

3. Cap cleaning of Fedar DTF printer: wipe edge of cap with a cotton swab dipped in cleaning fluid, once every 10 days, to keep it clean.

4. Replace cap for DTF printer: It is recommended to replace it every 3-4 months.

5. Replace damper: It is recommended to replace damper for Fedar DTF Printer every 3 months.

6. Encoder strip cleaning: Wipe both sides of encoder strip with a cotton swab dipped in alcohol, and clean it with pure water once a month to keep it clean.

7. Guide rail maintenance: maintain guide rail with grease every week.

8. Belt maintenance: check whether belt is worn out every three months.

Zhengzhou New Century Digital Technology Co., Ltd.,- (Fedar Printer:

www.fedar.net) has exquisite production technology and professional technical team in the field of fedar sublimation printers,inkjet heat transfer printer,digital fabric printer,etc., focusing on providing comprehensive solution for field of inkjet printing.

Fedar sublimation printer company has absorbed and condensed a group of high-quality professional technicians and enterprising young management groups, formed a strong technical team and increasingly rigorous management system,providing customers with high-quality printing machines and services,and has established a good brand image and reputation in industry.