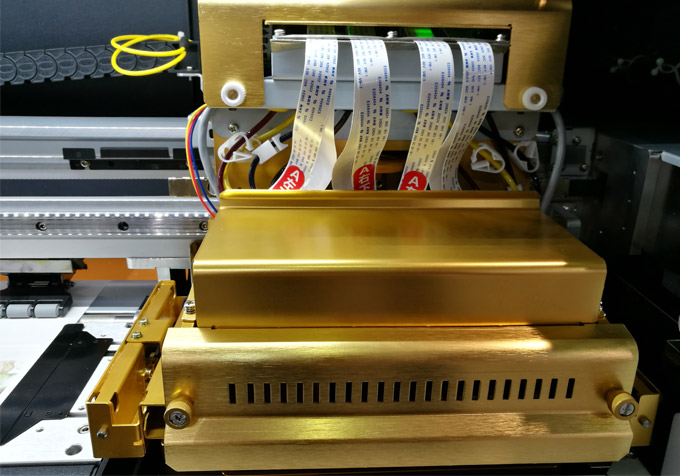

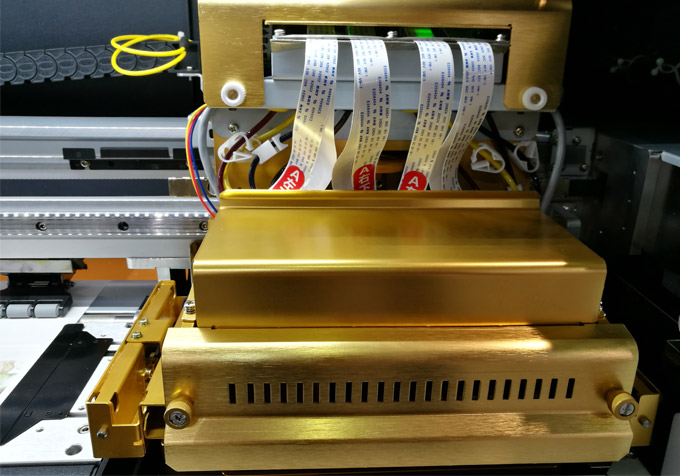

With the increasing use of sublimation printer, it is inevitable that you will encounter problem, especially print heads.

Fedar sublimation printer manufacturers list some behaviors that damage print head, which can allow users to reduce cost of print head and improve efficiency.

1. Use cleaning products without quality inspection

Fedar sublimation printer head is very easy to be contaminated and worn. If quality of cleaning tools is not good, it may cause secondary pollution to printhead. Be sure to ensure reliability of cleaning product before cleaning fedar sublimation printer head.

2. Do not pay attention to protecting circuit boards and other internal systems

Please turn off fedar sublimation printer’s power when cleaning, and be careful not to let water hit circuit board and other internal systems.

3. Use external force to irregularly adjust position of fedar sublimation printer head

Do not use brute force whether to replace or fine-tune print head. Please treat print head carefully according to specifications.

4. Do not pay attention to electrostatic protection

Fedar sublimation printer is greatly affected by static electricity, so you should not directly touch print head with your hands. Wear protective gloves when maintaining print head. You must also check connection of ground wire regularly. You can properly sprinkle a little salt water around ground wire regularly.

5. Long-term use of ultrasonic cleaning to clean fedar sublimation printer head

If you pay attention to maintenance of fedar sublimation printer head, there is no need for ultrasonic cleaning. Ultrasonic waves can cause adverse effects on printer head. Unless printer head is severely clogged, ultrasonic cleaning can be used, and cleaning time should not exceed 3 minutes.

Fedar sublimation printer head is core component of printing machine, so you must use correct method to clean and maintain print head to extend service life of print head.