28

Mar

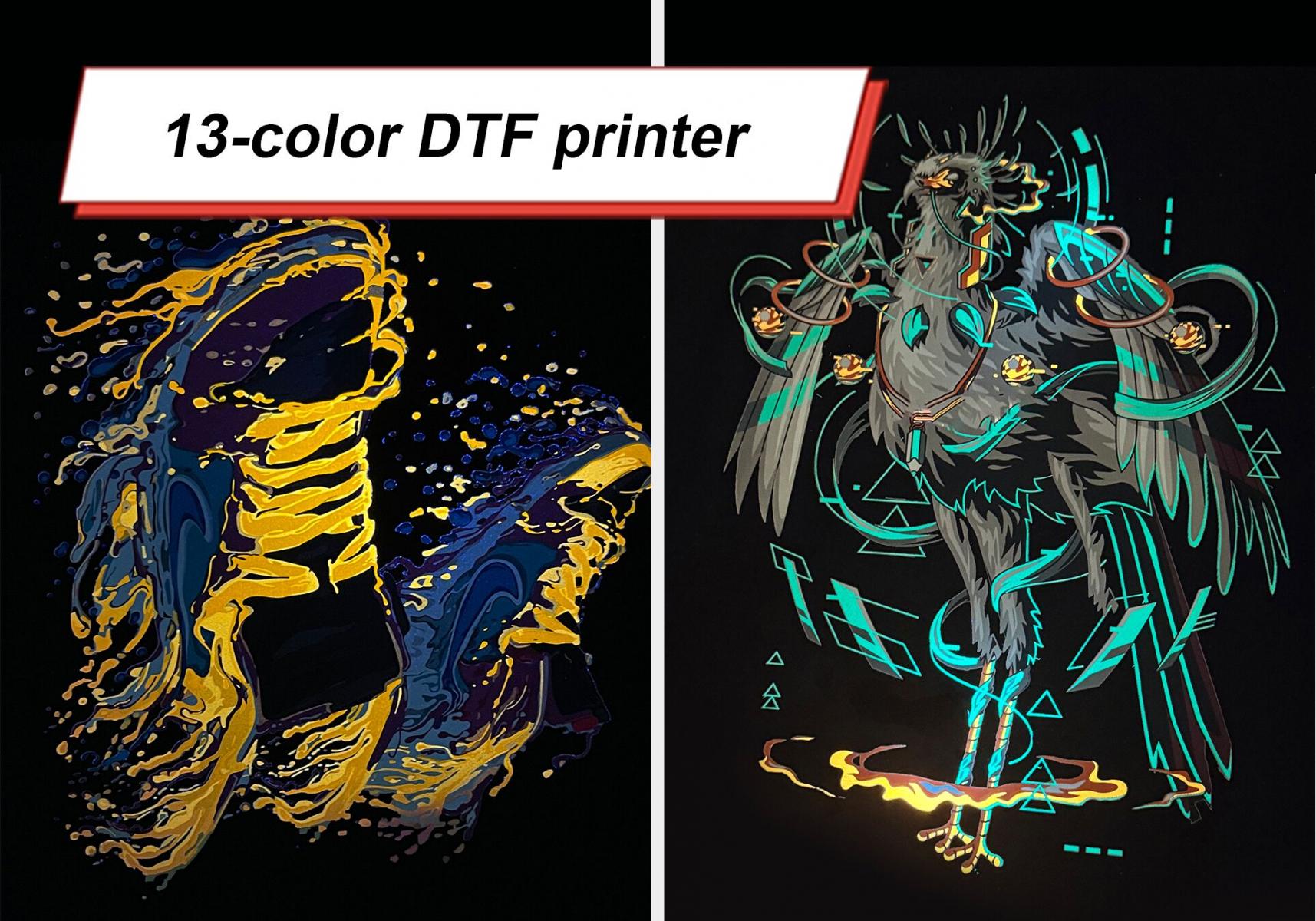

Explore the powerful performance of the 13-color DTF printer, which uses advanced multi-color direct printing technology to provide excellent hot-selling results. Whether it is high-end clothing or personalized products, this printer can meet all kinds of printing needs. With its default printing and environmentally friendly design, the 13-color DTF printer provides customers with innovative printing solutions to promote fast and efficient production. Enhance your printing experience and choose a technologically advanced digital printing device to create eye-catching works of art and commercial application effects.

A 13-color DTF printer (Direct to Film Printer) is a digital heat transfer device that uses a 13-color ink system. It can achieve ultra-high-precision pattern printing on DTF film, and then firmly attach the pattern to various fabrics through hot pressing transfer technology.

Compared with traditional 4-color and 6-color DTF printers, 13-color DTF printers can meet the stringent requirements of high-end customized clothing, sportswear, promotional gifts and other industries with a wider color gamut coverage and more accurate color reproduction. It is the latest breakthrough in the DTF printing industry.

1. 13-color high-precision inkjet, Pantone color matching degree 98%+

Adopt 4 Epson I3200 industrial-grade printheads, support 3200dpi ultra-high-definition printing, and more delicate details.

New spot color ink channel can accurately restore Pantone color cards to meet brand customization needs.

Suitable for complex gradients, 3D effects, photo-level pattern printing, far exceeding the effects of ordinary DTG printers and Dye-sublimation printers.

2. Industrial-grade stable production, 24-hour continuous operation

Fedar precision guide rails + Japanese servo motors ensure long-term printing without deviation, suitable for large-scale DTF printing processing.

Intelligent ink supply system, automatically detects ink residue, avoids the risk of ink shortage, and improves production efficiency.

3. Super strong adhesion, suitable for a variety of fabrics

Adopt high-viscosity white base ink, which can be firmly attached to materials such as cotton, polyester, nylon, blended, non-woven fabrics, etc., and will not fade after 50 washes.

Compared with traditional screen printing and heat transfer, DTF technology does not require plate making, can be printed in single pieces, and saves costs.

4. Environmentally friendly and low energy consumption, in line with international standards

Built-in two-stage exhaust gas purification system, effectively filters VOCs (volatile organic compounds), and complies with RoHS and CE certification.

Low energy consumption design saves 30% of electricity costs compared to traditional printing processes, suitable for environmentally friendly printing factories.

In general, a 4-head DTF machine printing 13 colors is equivalent to the speed of a 1-head machine. Because the speed of DTF depends on cmyk, the more color channels, the faster the printing speed.

1. Design pattern (AI/PS/CorelDRAW) → 2. Print DTF film (13-color inkjet) → 3. Powder curing (hot melt powder bonding) → 4. Hot pressing transfer (160-180℃ pressing) → 5. Finished product peeling (tear and use)

The whole process does not require plate making or pre-treatment, which is more efficient than Screen printing and DTG printing. It is particularly suitable for small batch customization, cross-border e-commerce, garment factory OEM and other business models.

✅ Clothing industry: T-shirts, sweatshirts, sportswear, yoga pants, denim printing

✅ Shoes, hats and bags: personalized printing of canvas shoes, baseball caps, backpacks, and canvas bags

✅ Home decoration: pillows and tablecloths customization

✅ Promotional gifts: corporate team building clothes, event souvenirs, advertising shirts, fast printing

.jpg)

✔ Wider color gamut: 10% more color range than 12-color DTF, more vivid printing effect

✔ Higher efficiency: 1000+ pieces per day, suitable for clothing processing factories and printing studios

✔ Lower cost: no plate making and no washing, saving 30% cost compared to traditional processes

✔ More environmentally friendly: no wastewater discharge, in line with market environmental protection requirements

With the growing demand for personalized customization and small-batch quick-response production, 13-color DTF printers are becoming the new favorite in industries such as clothing printing, personalized gifts, and home decoration due to their high color accuracy, strong adhesion, and multi-material applicability.

Consult now to get the latest DTF printer quotes and industry solutions!

If there's anything we can do to further showcase machines' features, please let us know.

Email: sale@fedar.net

Whatsapp: http://wa.me/8615515715397

Our company has over 30 models of printers with independent intellectual property rights and patents. Marketed under the esteemed brands of Skycolor, Stormjet, and Fedar brands, these printers cover a wide range, including digital textile printers, UV printers, eco-solvent printers and more. Known for their exceptional quality and performance.